Based on our study of Turkish rail construction, we found that there were four primary factors that kept construction costs low and the processes efficient. First, there was an ongoing political commitment spanning different administrations to build an extensive rail network in Istanbul. Second, through years of construction experience, initially learning from foreign experts brought in to consult and train the Turkish teams, and later collaborating with Turkish contractors and consultants who were now building rail all over the world, the agencies gained the capacity to streamline processes and manage projects efficiently. Third, market competition encouraged contractors and consultants to lower their costs, while developing their technical and technological capacities. Fourth, all parties involved quickly learned that speed saved money, and evolved their processes to avoid unnecessary delays. Ultimately, these conditions cultivated a competitive, agile and competent rail sector.

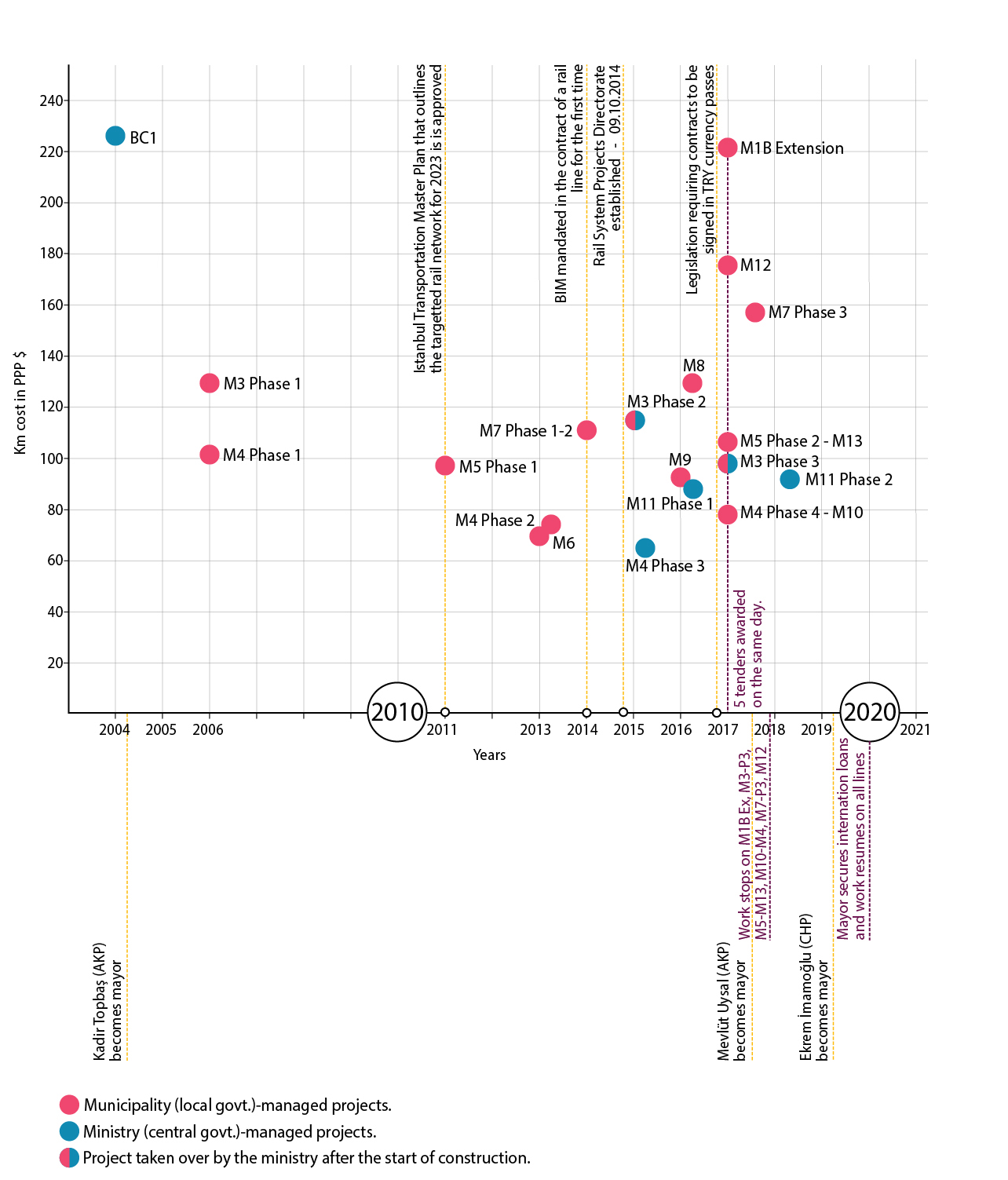

Throughout the last 20 years, the IMM has developed know-how and optimized its procurement processes to better manage rail construction projects. On the other hand, the AYGM under the central government has recently hired former IMM personnel as AYGM has begun to manage more projects in Istanbul. Since 2014, the IMM has utilized “final design for application” projects that are at 60% design, which has helped it go to construction tenders with more detailed information and better control over projects. In the earlier projects where the agency was still figuring out how to build subways, they would go to tenders with an underdeveloped preliminary design, leading to higher costs due to overdesign overseen by the contractors, as was the case for M4 and earlier projects. By the time the agency started working on M5, it knew enough to specify better optimized station and tunnel designs. The contractors we interviewed agree that this was one of the major changes that improved rail-construction processes; over the last 15 years, the agency has learned to spend more time on the design, working with experienced design consultants, prior to the construction tender.

Developing a good working relationship between public agencies and contractors has been critical to Istanbul’s success building more than 300 kilometers of heavy rail between 1989 and 2030. The agencies and contractors have struck this balance by tendering based on itemized costs and procuring the construction through as few contract packages as possible, which help the agency keep the process and costs under control. Additionally, agencies have expedited approvals and paperwork that allows for construction to start and advance quickly once the contract is signed. With the agency and contractor working together, the preliminary designs can be altered and innovative solutions can be developed quickly. While the costs are locked in through the contract, since the contracts are based on itemized costs, increases are allowed based on changes. However, the total increase is limited to 20% of the contract value. Increases beyond 20% need cabinet approval, which is almost always avoided to prevent delays. Nevertheless, through regular progress reports and payments, spending is kept under control by the agency. Additionally, multiple people whom we interviewed including one senior agency executive concluded that distributing risk among multiple contracts and contractors is unnecessary, and Istanbul saves money and time by avoiding breaking the work into multiple contracts (Personal Interviews G, J, L 2020 and P, V 2021).

It is not uncommon for a metro construction tender with a scope involving over 10 kilometers of tunnels to receive six or more bids, even when there are several lines under construction at the same time. The intense competition for metro construction encouraged contractors to innovate and bring their prices down. Contractors are motivated to win bids because there is a clear pipeline of new metro projects and many have invested in technology and expanded their equipment pools. Since 2014, Building Information Modeling (BIM) has been used in design, planning and management of construction, and it has been mandated through the agency’s contract specifications. Design consultants, construction managers and contractors rapidly adapted to the new requirements and all attribute their improved coordination and more efficient management of projects to BIM solutions. In addition to greater competition amongst general contractors, it is also now easier for contractors to buy or rent construction equipment, which reduces costs. Many contractors own TBMs, and keep costs low by utilizing the same machine on multiple projects. They also understand the specifications of the equipment better, and therefore can buy TBMs suitable for different soil conditions rather than changing cutter heads during construction, which slows down the pace of tunneling and adds costs.The agencies, contractors and consultants understand that speed saves money. The Environmental Impact Statement (EIS) certification and preliminary approval processes are rapid, and the contractor starts excavating as soon as the project’s rough boundaries, such as station exits and entrances, are determined. The contractors obtain pre-approval to start excavating before the designs are 100% complete and break ground, even though this sometimes means needing to do revisions. A senior manager we spoke to attributed Istanbul’s speed and lower costs to the Turkish teams’ ability to think outside the box (Personal Interview I 2020). The contractor and the agency develop quick solutions for problems that come up and find ways to work within the plans, standards and regulations. So the project ends up changing a great deal throughout the construction process, but is completed within the planned budget, or with the 20% allowable cost increase, and fast, relative to other countries in our database.A steady stream of projects, competition between the IMM and the Central Government’s Ministry of Transportation, as well as a robust pool of contractors vying for work has cultivated a productive rail-construction ecosystem in Istanbul. This benefits the city, even in cases where a contractor lacks experience, the agency, consultants, subcontractors with years of experience in the field along with the now established procurement mechanisms can make up for these shortcomings by helping the contractor learn on the job and deliver projects with minimal delays and cost overruns.

The Case Report

We have most recently updated this report on 02/11/2023.